DIFFERENTIATORS

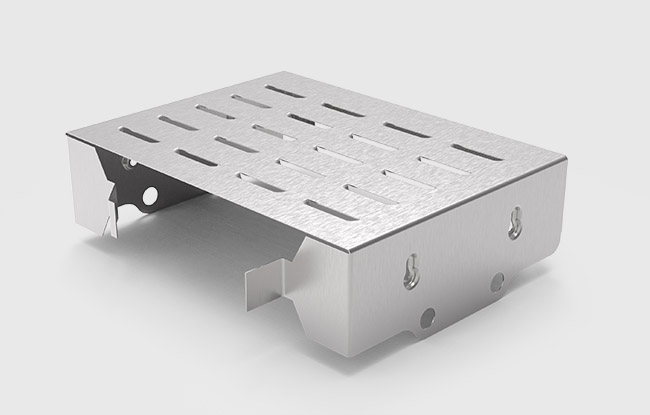

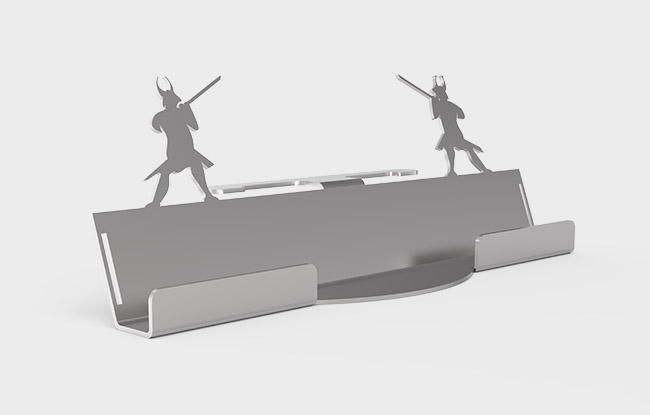

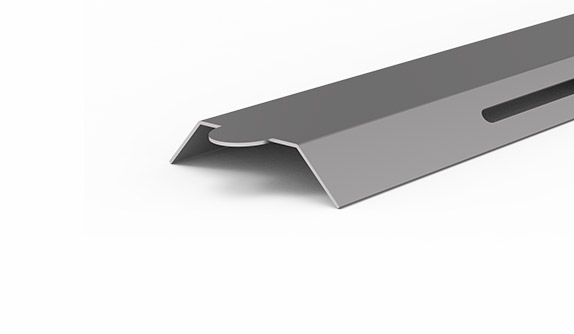

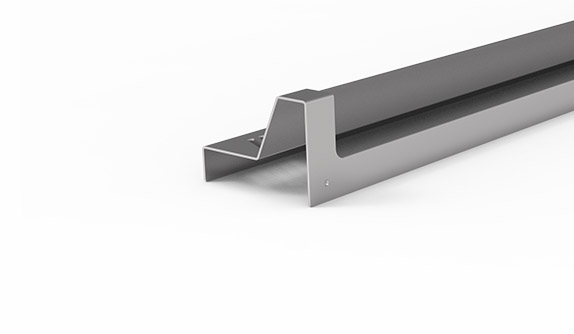

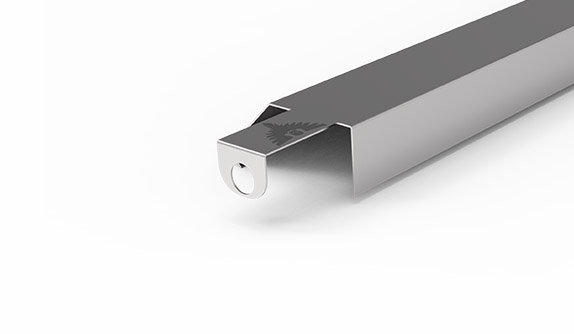

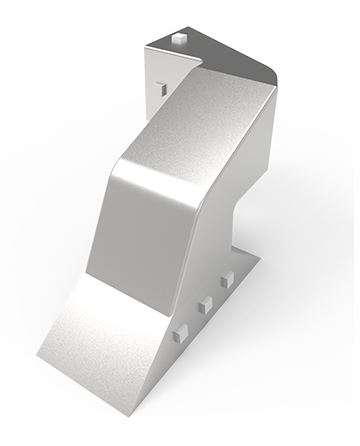

HIGH-PRECISION BENDING

Advanced servo-electric motion control ensures consistent accuracy, stable bending quality, and repeatable performance across every batch.

FASTER CYCLES & HIGH OUTPUT

Optimized bending sequences, intelligent tooling movements, and reduced setup time help manufacturers achieve greater productivity and lower cost-per-part.

SMART & FLEXIBLE DESIGN

Handles a wide variety of panel sizes, shapes, and thicknesses without mould changes—perfect for both custom fabrication and high-volume production.

INDUSTRY 4.0 READY

Seamless integration with automated lines, robots, and digital factory systems for real-time monitoring, data tracking, and minimal human intervention.

PRECISION

PERFORMANCE

OUR SERVICES

PRECISION

BENDING

ENGINEERING &

DEVELOPMENT

SMART PRODUCTION

INTEGRATION

CUSTOM FABRICATION

SUPPORT

TRAINING &

TECHNICAL SUPPORT

Trusted by Leading Manufacturers Around the World

Companies across sheet-metal fabrication, electrical enclosures, HVAC, automotive components, and precision engineering rely on RGNIC’s Panel Bending technology to elevate their production quality and efficiency.

WORK PROCESS

A streamlined, intelligent workflow ensures seamless setup, efficient bending, and consistent output for every manufacturing requirement.

PLANING

We analyze your production needs, material specifications, and bending requirements to design an optimized workflow for maximum efficiency.

DEVELOPMENT

Our engineering team configures the Panel Bender, programs bending sequences, and fine-tunes tooling to match precise product geometries.

DESIGNING

Advanced software tools help create accurate bending profiles, simulate part movements, and ensure consistent results across batches.

LAUNCH

Your production goes live with real-time monitoring, smooth automation, and expert support—ensuring flawless output from day one.

OUR TEAM

START TRANSFORMING YOUR SHEET-METAL PRODUCTION

Upgrade to smarter, faster and more precise panel bending with RGNIC’s advanced automation technology. Boost output, reduce errors and stay ahead in modern manufacturing.

EVERY INDUSTRY

MULTI-INDUSTRY PERFORMANCE